At Raymond we are constantly innovating and looking for safer and more efficient ways to build. We have the capability to prefabricate high performance load bearing panels to help advance the building enclosure process.

Load bearing panels can be used for buildings up to 10-stories and are delivered complete with all rough openings, headers, and bridging. They can include an Air Barrier System, and gypsum board that is installed on the walls can be any specified exterior drywall.

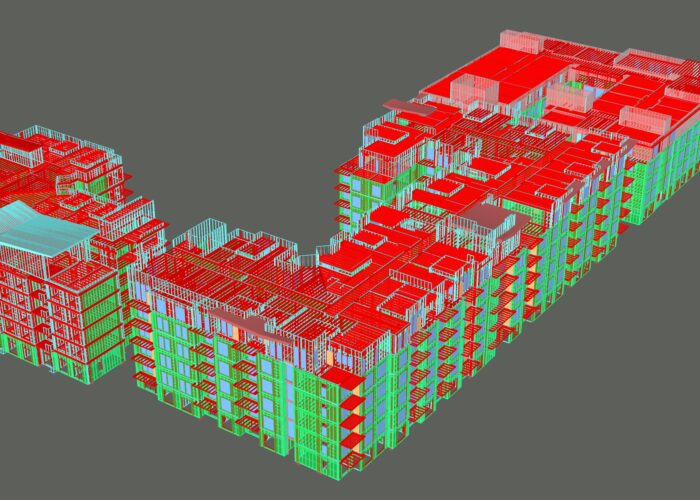

Recently in our Southern California facility, we have prefabricated load bearing structural framing and sheathing panels for Variel, a new luxury senior living facility comprised of three, eight-story buildings. To date, we have seen a reduction of manpower at the project site by approximately 30% and the schedule has been compressed which will allow for early occupancy of the building.

Raymond’s prefabrication process begins with Raymond’s in-house Virtual Design and Construction team, where the architectural design of the building and corresponding structural details are used to create a 3D model of the building. Through coordination efforts of all major trades, walls and floors are clash detected and blueprints for construction are processed.

From an established floor plan, panel tickets are created for construction. These tickets include all dimensions, openings, framing details and sheathing or sureboard requirements to guide the fabrication of each panel. Each panel is prefabricated per panel ticket details, to the exact specifications of the project. An extensive quality control process confirms the panel’s accuracy. Upon completion, Raymond coordinates just-in-time arrival of complete building enclosures.

The prefabrication of load bearing panels has proved beneficial in many ways. Easy installation means less labor at the project site. This reduces congestion and accidents. Scaffolding can be eliminated which removes complications and risks of working at high elevations.

Significantly for project owners, the prefabrication process allows for quicker installation which shortens the construction cycle. Buildings can become operational and begin generating revenue quicker.

LEARN MORE ABOUT LOAD BEARING PANELS HERE.